Breadcrumbs navigation

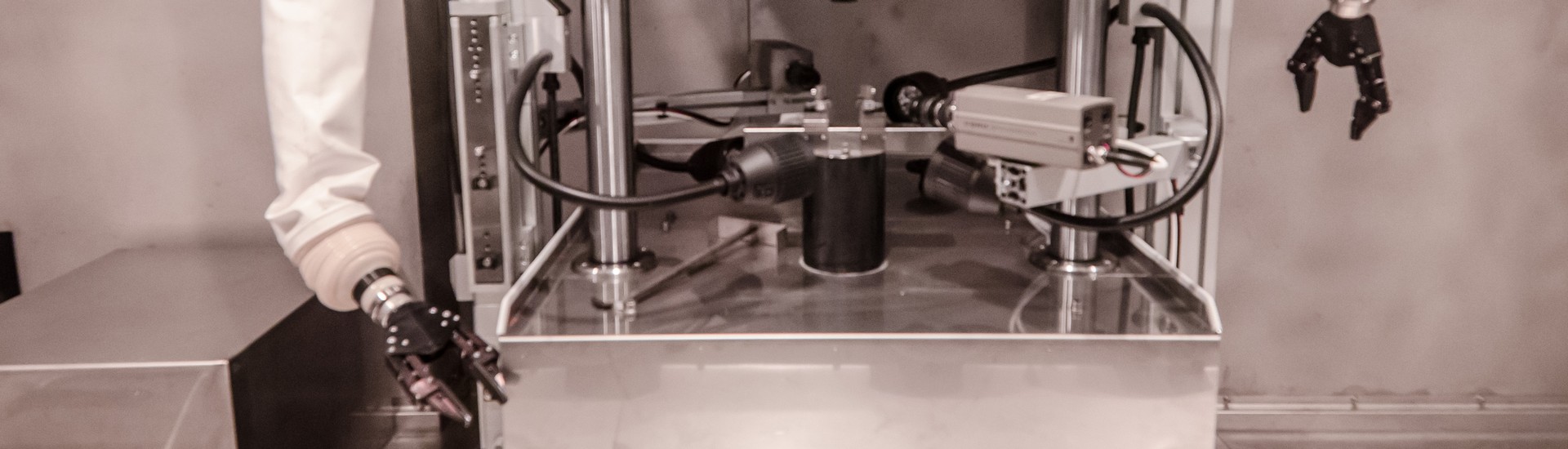

We have extensive experience and advanced infrastructure that allows us to perform mechanical tests on irradiated and non-irradiated materials, damage analyses, environmental qualification of the equipment, and degradation assessments of the NPP’s construction materials.

Power engineering materials and components are designed to operate for a specific period during which they have to meet the highest requirements of functionality, safety and durability in an aggressive environment (pressure, temperature, chemical effects).

Evaluating the degree of degradation of the construction materials and determining the extent of their deterioration due to different operating factors is an essential part of the lifetime management of a device.

Our services cover the comprehensive design and implementation of surveillance programmes and irradiation experiments, including subsequent analyses of material degradation and microstructure assessment of irradiated materials.