INTERNATIONAL PROJECTS

Since October 2020, 15 organizations from 7 European countries and Japan have been working together on a 4-years R&D project supported by the European Commission. A detailed description of the project structure, main goals, and roles of individual partners would be enough for a whole dedicated paper, therefore, in this section, only the main areas of R&D are listed, and their connection to key challenges in GFR research and development are discussed.

The SafeG project contains four technical work packages (WPs), a work package dedicated to training and education activities, and two work packages for communication and project management. The four R&D work packages are following:

— WP1: Core safety, proliferation resistance

— WP2: Innovative materials and technologies for enhancing the safety of GFRs

— WP3: Innovative solutions for decay heat removal

— WP4: Integration of the results, standardization, codes

The total effort to be spent on solving technical problems within these four WPs is 576 person-months or 48 person-years. TABLE 6 summarizes individual tasks of the WPs and their connection with the key challenges in GFR R&D.

SafeG webpage: www.safeg.eu

Additionally, in the framework of GIF, a project dedicated to conceptual design and safety of ALLEGRO has been ongoing, as well as a project on GFR fuel safety. Within the conceptual design and safety project, activities complementing the work done within the Czech national projects, and the SafeG project, have been ongoing, within Euratom and France collaboration. The GFR fuel safety project focuses mainly on the development of SiC-based cladding materials for GFRs. Euratom, France, and Japan have been collaborating on this task.

Under the UJV-CVR-JRC multilateral agreement, one project dedicated to GFR is ongoing, led by UJV Rez. It complements the Czech national project “NOVA”, using the unique equipment and know-how of JRC Karlsruhe in the field of precise measurements of thermo-physical properties of materials.

NATIONAL ACTIVITIES

Ongoing R&D on GFR in the Czech Republic

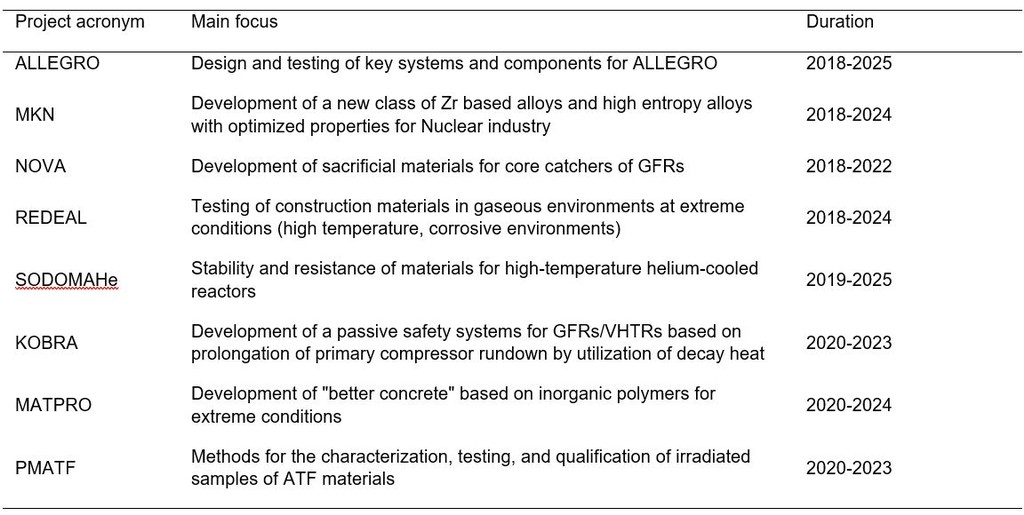

The main platform for national support of technology research and development in the Czech Republic is the Technology Agency of the Czech Republic (TACR). It is an organizational unit of the state that was founded in 2009 by Act No. 130/2002 Coll. on the support of research, experimental development and innovation. The creation of TA CR is one of the cornerstones of the fundamental reforms in research and development (R&D) in the Czech Republic. The key feature of the reform is the redistribution of financial support from the national budget. The Technology Agency of the Czech Republic simplifies the state support of applied research and experimental development which has been fragmented and implemented by many bodies before the reform. In the past 10 years, UJV Rez and CVR submitted a number of project proposals to various calls of TACR, resulting in more than 10 projects actually supported by the organization, 8 of them being currently ongoing. The ongoing projects are listed in the following table.

As can be seen from the data listen in the table, the majority of the ongoing projects is focused on material development since it was identified as the most pressing area. Safety research and development of systems and components closely follows.

Another notable achievement is the successful full commissioning of an electrical heated 1 MW mock-up of GFR called S-ALLEGRO in 2020. This facility plays a key role in thermal-hydraulics and safety research of GFRs and will be a vital part of higher-TRL development and testing of systems and components in the near future.

GFR R&D in Hungary

In Hungary, a major national project on GFR was finished in 2018. With the recent reform of the Hungarian Academy of Sciences, an individual entity “Center for Energy Research” (EK) was formed, and the development of the ALLEGRO reactor is one of its research priorities. Since 2019, EK, alongside several universities and private companies, are the leading entities in GFR research in Hungary, with a focus on reactor physics and nuclear fuel, safety, and thermal-hydraulics.

GFR R&D in Poland

In Poland, there is currently no ongoing national project focused primarily on GFR technology. However, the Polish HTR program is very broad, with several substantial R&D projects ongoing, and with a plan for a fast deployment of an HTR prototype designed in Poland. Since there is a high number of cross-cutting R&D issues between the HTR and the GFR technologies, experience and results obtained from these projects are valuable contributions to the development of ALLEGRO.

GFR R&D in Slovakia

In Slovakia, a major national project on ALLEGRO development finished in 2015, focused on the building competencies and development of the concept. One of the major achievements of the Slovakian GFR program is the successful commissioning and operation of the STU helium loop – an experimental facility aimed at the study of natural convection in helium-cooled reactors. First experimental results were already obtained and published.