Breadcrumbs navigation

At the EPRI NDE TechWeek 2024 Conference in the USA, our colleague Daniel Dopjera presented the possibilities offered by MVM1, a specialised software for creating virtual test specimens. This method of generating artificial weld defects in industrial operations offers significant benefits for power plant operators and for the training of personnel responsible for inspecting weld joints and identifying potential issues.

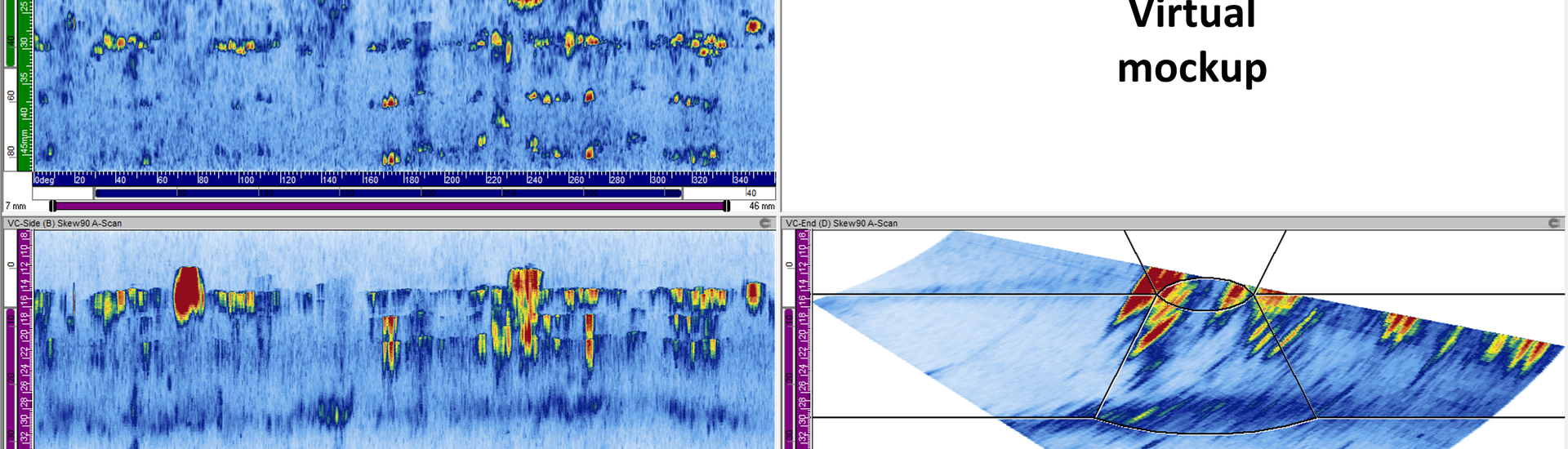

The current practice of non-destructive testing – manufacturing real test specimens with artificial defects for individual types of welds – is a relatively expensive and time-consuming process. Virtual test specimens are artificially created ultrasonic data, which can also be interpreted in a 3D model, allowing much faster simulation of various discontinuity scenarios. However, there is a significant “but” to this seemingly straightforward “IT operation”. To be effective, the virtual specimens must simulate discontinuities that correspond to those that could actually occur in power plant operations. This is precisely where the extensive experience of Daniel Dopjera and his team plays a crucial role. They bring years of practice with real ultrasonic inspections and the application of Phased Array Ultrasonic Testing (PAUT) technology in diverse industrial settings — including nuclear power plants — both in the Czech Republic and abroad.

Building a database of virtual test specimens, or more precisely, data on various discontinuities, not only significantly expands opportunities for training and periodic assessment of operational inspectors, but also serves as an important source of information for machine learning in advanced robotic manipulators. The integration of artificial intelligence into operational practice will, in the near future, enable very rapid routine inspection of large volumes of data and the identification of potentially problematic areas. These can then be further examined by NDE (Non-destructive Evaluation) inspection personnel.

The MVM1 software used by our colleague Dopjera for virtual specimen testing, was provided by the Electric Power Research Institute (EPRI). ČEZ has been a member of EPRI’s nuclear sector since 2011, and ÚJV Řež, as a subsidiary, has been significantly involved in EPRI’s activities. We have already received several awards from EPRI for our contributions to global knowledge regarding the safe operation of nuclear power plants.