Breadcrumbs navigation

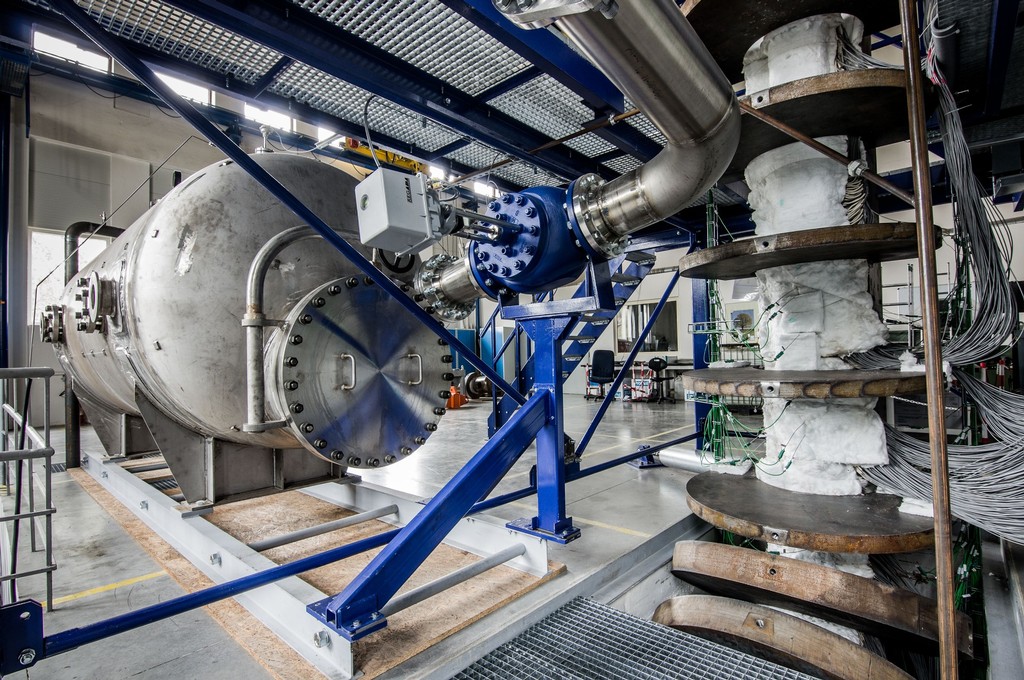

There are several unconventional facilities at the ÚJV Řež site, but the THS-15 thermohydraulic test facility is unique worldwide. This experimental installation, simulating the full-scale dimensions of a reactor pressure vessel, was designed and manufactured in Řež to verify procedures for ensuring reactor vessel integrity in the event of hypothetical severe accidents involving core melt and the formation of corium. Using this unique experimental facility, the feasibility of retaining corium inside the Reactor Pressure Vessel (RPV) is tested through the application of external cooling—known as the IVMR strategy (In-Vessel Melt Retention by External Reactor Vessel Cooling).

The story of THS-15 began after the Fukushima accident in Japan, which served as a reminder that complacency has no place in nuclear safety and that continuous improvement of nuclear power plant safety is essential. The facility was designed by specialists from the Integrity and Technical Engineering Division, while the custom manufacture of atypical components, followed by assembly and commissioning of the experimental stand, took two years. The conceptual originator of the facility is our colleague Jiří Žďárek, who also played a key role in its final implementation.

Since the start of operation in 2018, a series of successful tests has been carried out, confirming the suitability of the IVMR safety approach for higher-power VVER reactors (the HORIZON project). Currently, THS-15 is being used to verify the applicability of this strategy within European small modular reactor projects, in particular the EASI-SMR (European Advanced Small Modular Reactor) project. The experiments provide essential input for computational thermohydraulic codes and thus enable an enhanced level of safety analysis for future nuclear power plant projects, especially SMRs.