Breadcrumbs navigation

As part of the special supervisory audit of the Czech Institute for Accreditation, tests of miniaturised thin sheet samples (SPT, Small Punch Test) were included among the accredited experimental methods implemented pursuant to the latest standard ASTM E3205-20 in the laboratory of the Mechanical Properties Department (2303), Integrity and Technical Engineering Division, at the end of 2020.

Starting from this January, it is therefore possible to fully use this method for the testing of irradiated and un-irradiated materials in accordance with the globally recognised technical standard. The rapid implementation of all requirements of the new standard and the smooth performance of the audit were the result of co-operation of a team of all employees of department 2303, particularly Pavel Pešek, Ondřej Buršík, Marek Augulis and Michael Rapp.

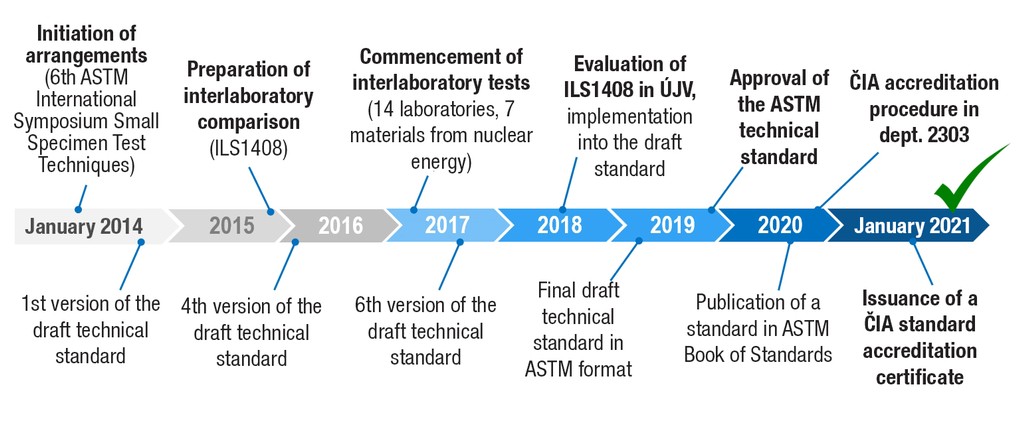

Accreditation of the test method pursuant to the globally recognised standard marked the successful completion of a seven-year process which, from the beginning of the development of the standard in January 2014, was initiated and managed by ÚJV Řež, a.s. as part of its long-term membership in ASTM (Dr. Milan Brumovský and Radim Kopřiva, Ph.D.). The organisation of an extensive international comparison of test results obtained from 14 laboratories (USA, Japan, United Kingdom, Germany, Spain, China, India, South Korea, Slovakia) associated with the assessment of 7 different structural materials in the field of nuclear energy was an integral part of this process. The use of an accredited procedure for the testing of miniaturised samples enables the possibility of material parameters determination, even in the case of a very limited available amount of the structural material and is also one of the perspective methods for the analysis of new, promising materials, e.g. produced by additive metallurgy methods.

Application of the method is not only limited to laboratory conditions – its use is associated with proven technologies for the sampling of structural materials from components in real operation without affecting their integrity and function. The Integrity and Technical Engineering Division, Energy Equipment Operation Support Department (2302, Martin Kronďák, Ph.D.), uses a sampling device which allows direct collection of material for subsequent tests of mechanical properties and chemical and structural analyses of materials in industrial and energy plants.

The Integrity and Technical Engineering Division thus expands its portfolio of services with a new comprehensive chain of activities, from the sampling of structural materials of operating components to the assessment of their mechanical, chemical and structural properties with the support of internationally recognised standards. In these activities, the Division is ready to be a reliable partner for the complex implementation of experimental activities and analyses, and not only in projects undertaken by the ÚJV Group.